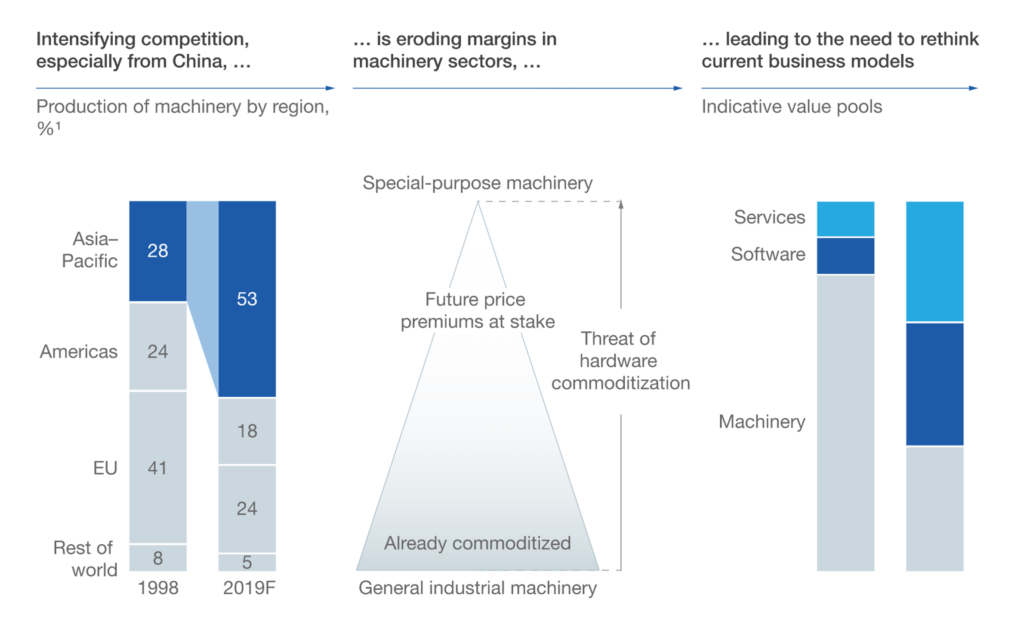

The manufacturing industry is moving away from just selling machinery, devices, and other hardware. Software and services increase revenue and margins. A former cost center becomes a profit center for innovation. Equipment-as-a-Service (EaaS) even outsources the maintenance to the vendor. This paradigm shift is only possible with reliable and scalable real-time data processing leveraging an event streaming platform such as Apache Kafka. This post explores how the next generation of software for Condition Monitoring and Predictive Maintenance can help build new innovative products and improve the OEE for customers.

Condition Monitoring and Predictive Maintenance

Let’s define the two terms first as no standard definition exists. Some literature sees condition monitoring as a major component of predictive maintenance. However, others interpret the latter as a more modern software leveraging machine learning. Both terms are sometimes used as synonyms, too.

Modern Maintenance Strategies and Goals

The main goal of modern maintenance strategies is a more efficient and optimized usage of machines and resources. Reactive maintenance or time-based/usage-based preventive measurements are suboptimal. Therefore, modern condition-based maintenance strategies take over.

Industrial IoT / Industry 4.0 enable several benefits on the shop floor level:

- Maintain instead of repair

- No (un)planned downtime

- Maintenance optimizations and no unnecessary work

- No negative financial impact

- Optimized productivity

- Improved overall equipment effectiveness (OEE)

- Move from an isolated to a company-wide view

The machine operator is interested in the following questions:

- Is the machine running normally? (Detect anomalies, classify errors)

- How long can the engine still run? (Remaining useful life – RUL, time to the first failure)

- Why does the machine run abnormally? (Sensor monitoring, root cause analysis)

Condition Monitoring and Predictive Maintenance

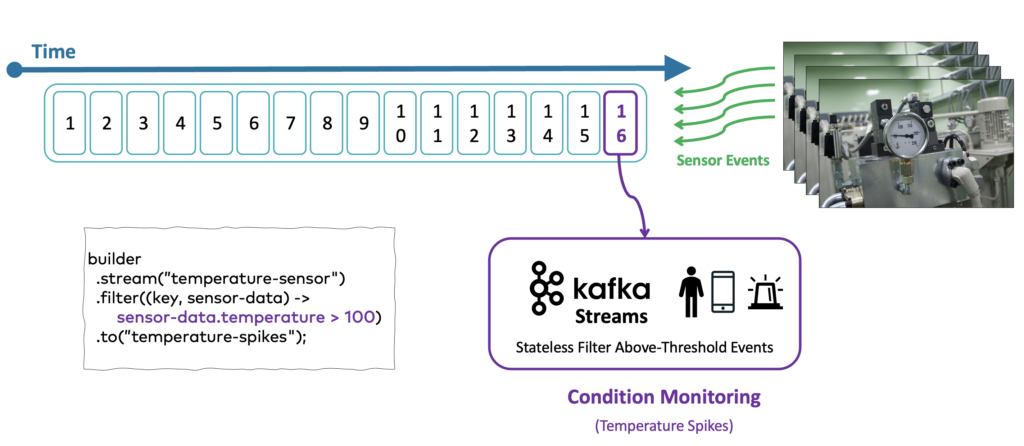

Condition Monitoring is the process of monitoring a parameter of condition in machinery (vibration, temperature, etc.) to identify a significant change indicative of a developing fault. It is a substantial component of predictive maintenance. The use of condition monitoring allows scheduling maintenance or taking other actions to prevent consequential damages and avoid its consequences. Condition monitoring has a unique benefit: It addresses conditions that shorten the expected lifespan before developing into a major failure.

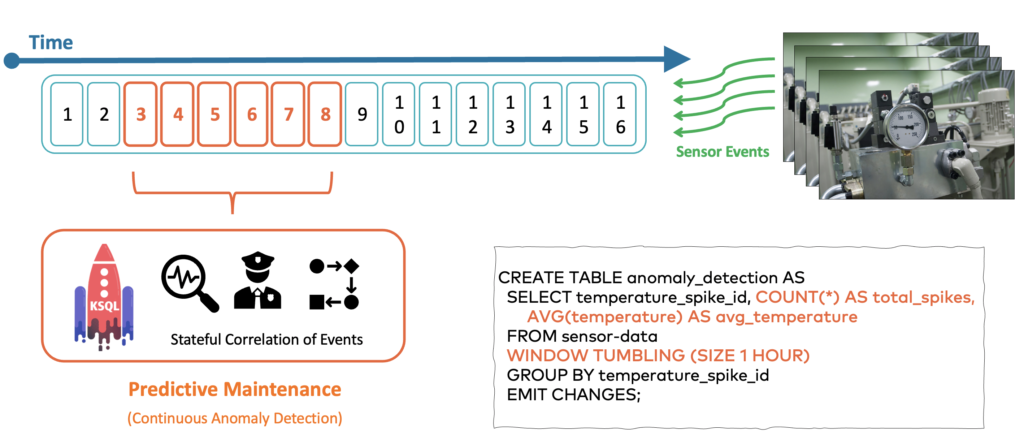

Predictive maintenance techniques help determine the condition of in-service equipment to estimate when maintenance is necessary. The central promise of predictive maintenance is to allow convenient scheduling of corrective maintenance and prevent unexpected equipment failures.

TL;DR: Both approaches promise cost savings over routine or time-based preventive maintenance because maintenance tasks only are performed when warranted. However, modern maintenance means digitalization. That does not come for free.

Condition monitoring and predictive maintenance only work well if the infrastructure and software are reliable, scalable, and real-time. The main trade-off is a reasonable risk and costs analysis to plan the total cost of ownership (TCO) and return on investment (ROI).

Equipment as a Service (EaaS) as new Business Model

Equipment-as-a-Service (EaaS) is a business model that involves renting out equipment to end-users and collecting periodic subscription payments for using the equipment.

This service-driven business model, also known as Machine-as-a-Service, provides a variety of benefits to both sides:

- The EaaS provider (OEMs and machine builders) can improve the product design (R&D, digital twin, etc.), plan recurring revenue, and provide predictive maintenance services.

- The customer (manufacturers) can optimize machine utilization and productivity (with the help of the EaaS software) and reduce the overall cost (moving Capital Expenditures (CapEx) to Operating Expenses (OpEx) and reducing operations costs).

EaaS is only a successful business model if condition monitoring and predictive maintenance are stable 24/7 and continuously collect, process, and analyze incoming data streams.

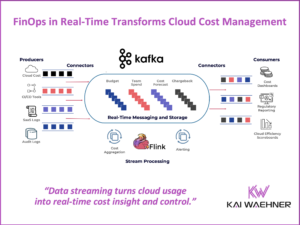

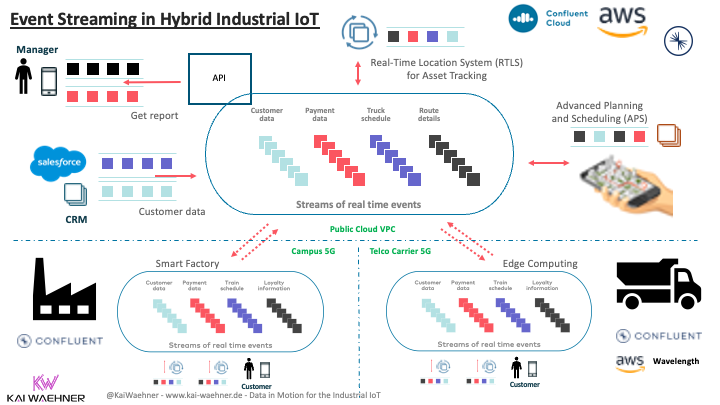

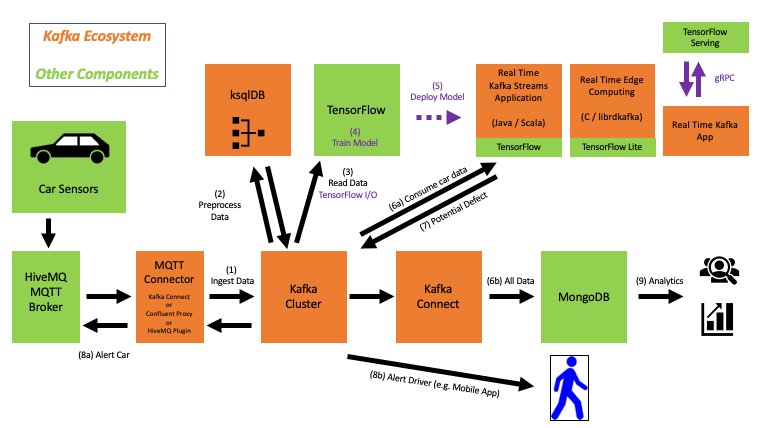

Apache Kafka for Industrial IoT / Industry 4.0

Data in Motion with Event Streaming and Stream Processing

Stateless Condition Monitoring with Kafka Streams

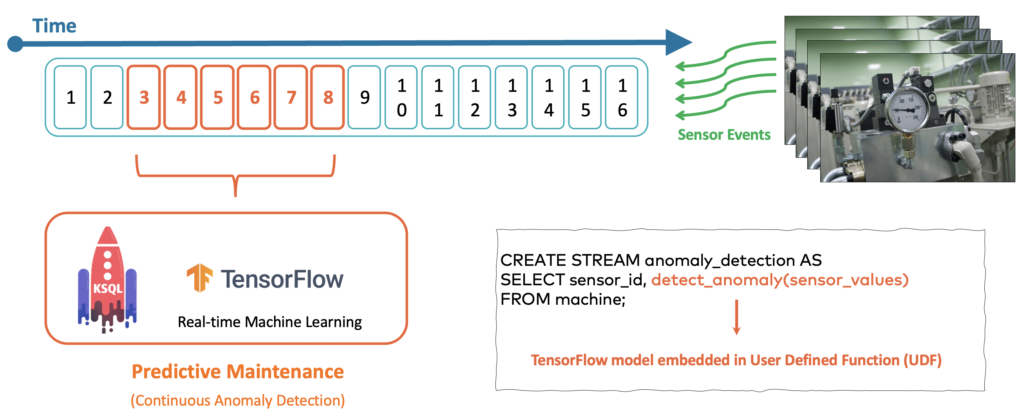

Stateful Predictive Maintenance with ksqlDB

Applied Machine Learning in Real-time with Kafka and TensorFlow

- Introduction to Kafka and Machine Learning for Model Training and Deployment

- Architectures and Trade-Offs for Model Serving and Scoring with Kafka

- Streaming Machine Learning with Kafka-native Model Deployment

- Code Examples using Kafka, Streams, ksqlDB, TensorFlow, DL4J, H2O and, more

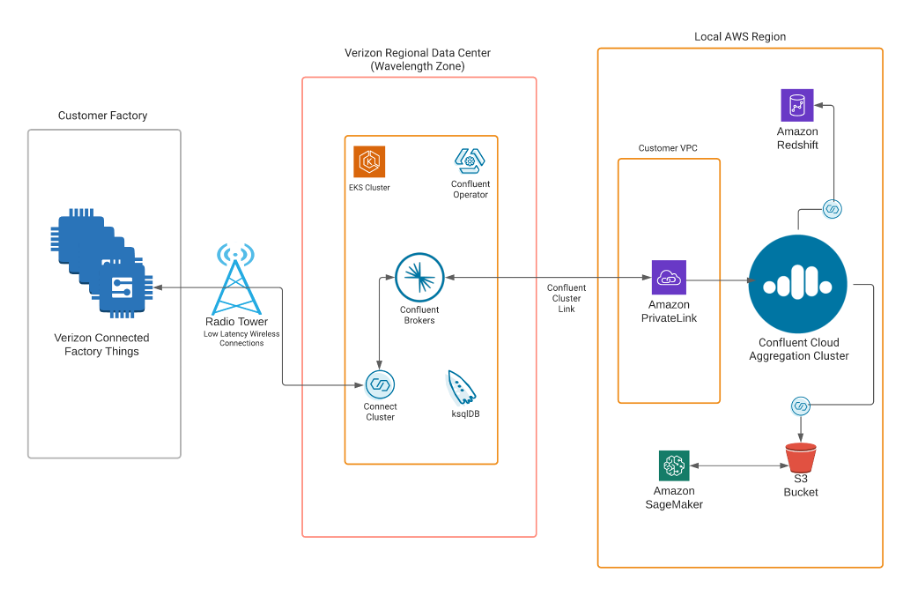

Equipment-as-a-Service with Fully-Managed Kafka

- Use Cases for Digital Twins with Kafka

- IoT Architectures for a Digital Twin and Digital Thread with Kafka

- Serverless Kafka for Managed Event Streaming to Focus on Business Logic

- Comparison of Apache Kafka Products, Vendors, and Cloud Services

Video Recording – Apache Kafka in Industrial IoT